Technical advice for choice

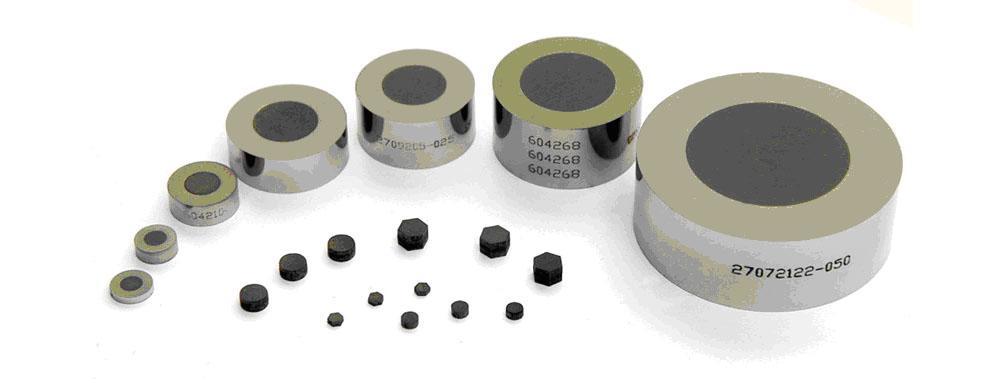

of PCD blanks with a wide choice of possibilities adapted to each application

(Copper, Alluminium, Steel, Alloys..... etc) and taking into account your

Specifications & performance requirements.

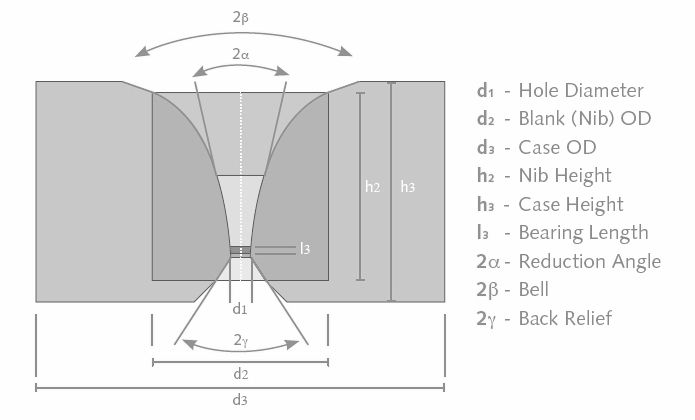

Consistency of the geometry and high level of surface polish for you to

achieve the best results in terms of surface finish, tight tolerances, dies

performance and to protect your lubricants. Also, get significantly longer die

life.